ABOUT US

We bring your jewelry to life!

Our mission is to help you transform your ideas from paper to finished jewelry. Exactly the way you envisioned it.

We believe in taking the time to plan your design. The result is beautiful jewelry, made exactly how you want it. The sketch of your design will have all the dimensions and stone sizes that will be used on your jewelry, carefully calculated to make sure that your design can be manufactured within your desired budget. Our team of CAD designers will render your jewelry so you can see how it will look once it is done.

We believe in producing jewelry of the highest standards. We use state of the art technology and the latest manufacturing equipment to deliver the best quality possible.

There is no minimum order quantity with us. It is one of the aspects that makes our organization so great. Our ordering systems allow for you to practice Just In Time inventory systems and place your orders with us according to your distributors orders to you. Our larger clients sometimes place 10 – 50 orders per day according to their distributions. Orders can contain anywhere from one piece to many thousands of pieces.

Most people can never find jewelry they want, because it was made by someone else for someone else. At Artchy Jewelry, we encourage you to make your own jewelry. The way you want it!

PRE PRODUCTION

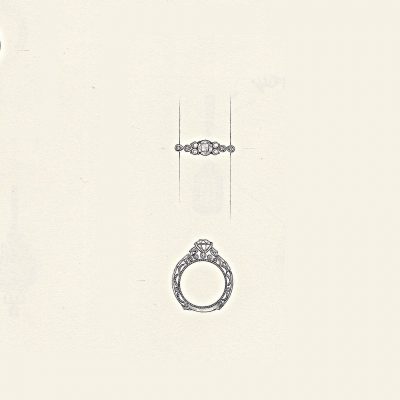

Sketch Designing

Hand drawn sketches or Photoshop / Illustrator is used to design your jewellery.

CAD/CAM Designing

3D CAD (computer-aided design) of your jewellery is made using JewelCAD, Rhino/Matrix, zBrush software.

3D Rendering

3D CAD files are rendered to photorealistic jewellery. Blueprints are generated to show dimensions, estimated metal weights and gemstone sizes.

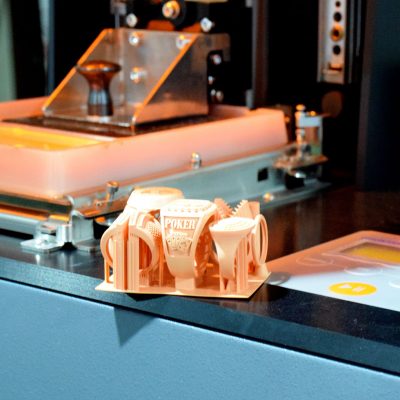

RP 3D Printing

3D CAM (computer aided manufacturing) files are 3D (castable wax resin) printed using RP (rapid prototyping) EnvisionTEC high resolution printers.

CNC Machining

3D CAD files are 3D mill printed using 4 axis Roland CNC machine.

HAND WAX Carving

Jewellery is hand carved / sculptured using castable wax.

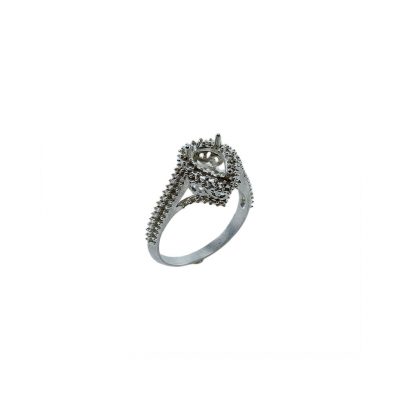

Master Making

Wax models are cast and filed to master models / mountings.

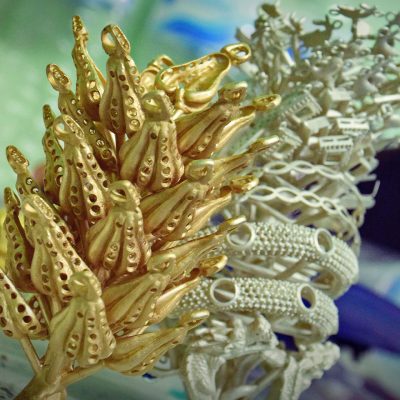

Molding

Masters are silicon / rubber moulded for jewellery production.

PRODUCTION

Casting

Moulds are wax injected and cast in brass, silver and (10k/14k/18k) gold.

Filing and Assembly

Cast pieces are filed, assembled and polished to mountings ready for stone setting.

Microscope Setting

Each stone is securely (bezel, prong, channel, bead, invisible) set on the mounting.

Polishing and Plating

Jewellery is high polished / sand blasted / satin finished and plated your desired colour.

Laser Engraving

Personalised names, logos, purity stamps are laser engraved on your jewellery

Enamel

Enamel is used to add colour to your jewellery.